Dûbele toanhichte tandwielen neffens Aziatyske standert

NK2040SB

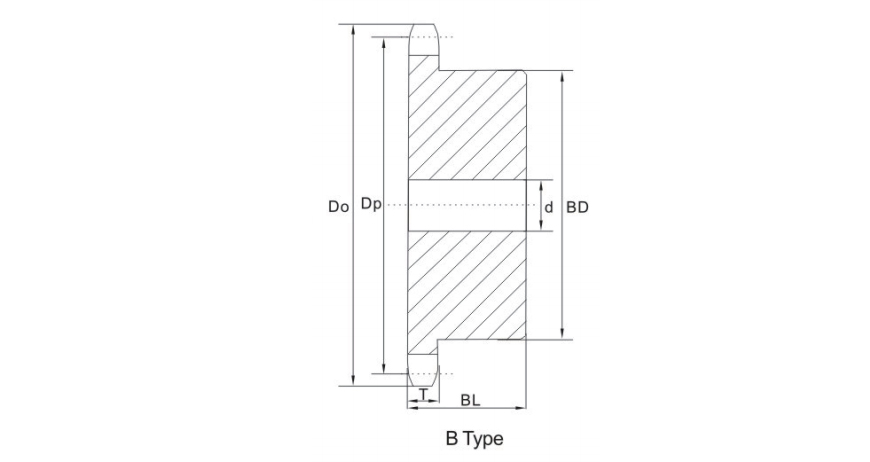

| TANDWIELEN | mm |

| Toskbreedte (T) | 7.2 |

| KETTING | mm |

| Toanhichte (P) | 25.4 |

| Ynterne breedte | 7,95 |

| Rol Φ (Dr) | 7,95 |

| Type | Tosken | Do | Dp | Ferfeeld | BD | BL | Gewicht kg | Materiaal | ||

| Foarrie | Min. | Maks | ||||||||

| NK2040SB | 6 1/2 | 59 | 54.66 | 13 | 15 | 20 | 35 | 22 | 0.20 | C45 Fêst |

| 7 1/2 | 67 | 62.45 | 13 | 15 | 25 | 43 | 22 | 0.30 | ||

| 8 1/2 | 76 | 70.31 | 13 | 15 | 32 | 52 | 22 | 0.42 | ||

| 9 1/2 | 84 | 78.23 | 13 | 15 | 38 | 60 | 25 | 0.61 | ||

| 10 1/2 | 92 | 86.17 | 14 | 16 | 46 | 69 | 25 | 0.82 | ||

| 11 1/2 | 100 | 94.15 | 14 | 16 | 51 | 77 | 25 | 0.98 | ||

| 12 1/2 | 108 | 102.14 | 14 | 16 | 42 | 63 | 25 | 0.83 | ||

NK 2050SB

| TANDWIELEN | mm |

| Toskbreedte (T) | 8.7 |

| KETTING | mm |

| Toanhichte (P) | 31.75 |

| Ynterne breedte | 9.53 |

| Rol Φ (Dr) | 10.16 |

| Type | Tosken | Do | Dp | Ferfeeld | BD | BL | Gewicht kg | Materiaal | ||

| Foarrie | Min. | Maks | ||||||||

| NK2050SB | 6 1/2 | 74 | 68.32 | 14 | 16 | 25 | 44 | 25 | 038 | C45 Fêst |

| 7 1/2 | 84 | 78.06 | 14 | 16 | 32 | 54 | 25 | 0.55 | ||

| 8 1/2 | 94 | 87.89 | 14 | 16 | 45 | 65 | 25 | 0-76 | ||

| 9 1/2 | 105 | 97.78 | 14 | 16 | 48 | 73 | 28 | 1-06 | ||

| 10 1/2 | 115 | 107,72 | 14 | 16 | 48 | 73 | 28 | 1.16 | ||

| 11 1/2 | 125 | 117.68 | 16 | 18 | 48 | 73 | 28 | 1.27 | ||

| 12 1/2 | 135 | 127.67 | 16 | 18 | 48 | 73 | 28 | 1.40 | ||

NK 2060SB

| TANDWIELEN | mm |

| Toskbreedte (T) | 11.7 |

| KETTING | mm |

| Toanhichte (P) | 38.10 |

| Ynterne breedte | 12.70 |

| Rol Φ (Dr) | 11.91 |

| Type | Tosken | Do | Dp | Ferfeeld | BD | BL | gewicht kg | Materiaal | ||

| Foarrie | Min. | Maks | ||||||||

| NK2060SB

| 6 1/2 | 88 | 81.98 | 14 | 16 | 32 | 53 | 32 | 0.73 | C45 Fêst

|

| 7 1/2 | 101 | 93.67 | 16 | 18 | 45 | 66 | 32 | 1.05 | ||

| 8 1/2 | 113 | 105.47 | 16 | 18 | 48 | 73 | 32 | 133 | ||

| 9 1/2 | 126 | 117.34 | 16 | 18 | 55 | 83 | 40 | 203 | ||

| 10 1/2 | 138 | 129.26 | 16 | 18 | 55 | 83 | 40 | 2.23 | ||

| 11 1/2 | 150 | 141.22 | 16 | 18 | 55 | 80 | 45 | 256 | ||

| 12 1/2 | 162 | 153.20 | 16 | 18 | 55 | 80 | 45 | 281 | ||

Dûbele toanhichte transportkettingtandwielen binne faak ideaal foar it besparjen fan romte en hawwe in langere libbensdoer as standert tandwielen. Geskikt foar kettingen mei in lange toanhichte, dûbele toanhichte tandwielen hawwe mear tosken as in standert tandwiel mei deselde toanhichtesirkeldiameter en ferdiele slijtage evenredich oer de tosken. As jo transportketting kompatibel is, binne dûbele toanhichte tandwielen perfoarst it beskôgjen wurdich.

Tandwielen foar dûbele steek rolkettingen binne beskikber yn in ien- of dûbeltoskich ûntwerp. Ientoskede tandwielen foar dûbele steek rolkettingen hawwe itselde gedrach as standert tandwielen foar rolkettingen neffens DIN 8187 (ISO 606). Troch de gruttere kettingsteek fan dûbele steek rolkettingen is it mooglik om de duorsumens te fergrutsjen troch modifikaasjes fan tosken.

Standert rollertype tandwielen hawwe deselde bûtenste diameter en breedte as it ien-pitch-ekwivalint, allinich mei in oar toskprofyl om de ketting goed te pleatsen. By even tosken gripe dizze tandwielen allinich om de oare tosk yn 'e ketting, om't der twa tosken per pitch binne. By ûneven tosken gript elke tosk allinich om de oare omwenteling yn, wat fansels de libbensdoer fan it tandwiel ferlingt.