Lasnaven, type W, WH, WM neffens C20 materiaal

Las-op-hubs

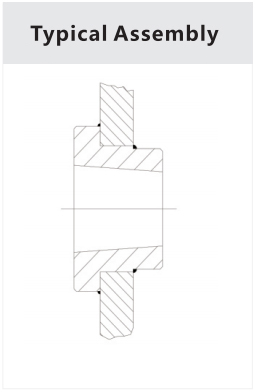

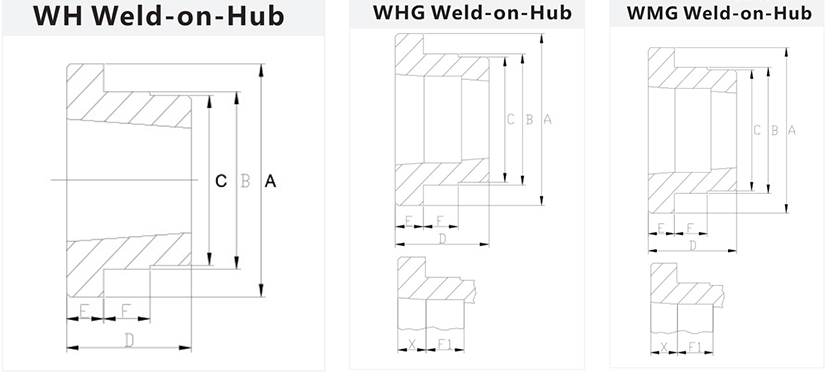

Taper Bore Weld-on-Hubs binne makke fan stiel, boarre, tapt en taps boarre om standert Taper Bushes te ûntfangen. De útwreide flens biedt in handige manier om naven te lassen yn fanrotors, stielen katrollen, platentandwielen, waaiers, roerders en in protte oare apparaten dy't stevich oan 'e as befestige wurde moatte. Weld-on-Hubs binne maklik te ynstallearjen en folslein geskikt foar gebrûk wêr't swiere wurkomstannichheden foldogge. It oandraaien fan 'e skroeven ferminderet de boring fan' e bus, wêrtroch't it oan 'e as liket op in perspassing. Dit type konstruksje elimineert montageproblemen, it foarkomt ek losmeitsjen en slijtage fan 'e naaf tidens operaasje. Weld-on-Hubs wurde produsearre om it Taper Bush-berik oan te foljen en omfetsje W, WG, WH, WHG, WM en WMG Taper Bore Hubs. Alle wurde produsearre neffens wrâldnoarmen mei C20 stiel.

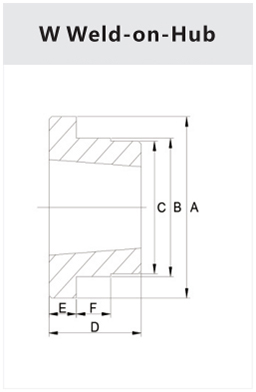

W Las-op-hubs

| Hub | Bushgrutte | A | B | C | D | E | F | Fl | X |

| W12 | 1215 | 73.03 | 63.50 | 62.71 | 38.10 | 15.88 | 9.53 | - | - |

| W16 | 1615 | 82.55 | 73.03 | 72.24 | 38.10 | 15388 | 9.53 | - | - |

| W25 | 2517 | 127.00 | 111.13 | 110.34 | 44.45 | 19.05 | 12.70 | - | - |

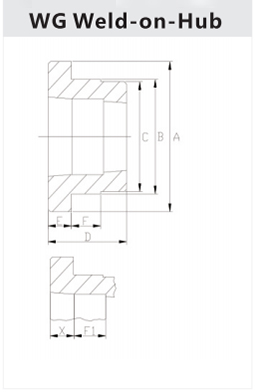

| WG30 | 3030 | 149.86 | 133.35 | 132.56 | 76.20 | 25.40 | 19.05 | 23 | 23 |

| WG35 | 3535 | 184.15 | 158,75 | 157.96 | 88.90 | 31.75 | 25.04 | 30 | 30 |

| WG40 | 4040 | 225.43 | 169.85 | 196.06 | 101.60 | 31.75 | 31.75 | 34 | 34 |

| WG45 | 4545 | 254,00 | 222.25 | 221.46 | 114.30 | 38.10 | 38.10 | 38 | 38 |

| WG50 | 5050 | 267,00 | 241.00 | 240.25 | 127.00 | 38.10 | 38.10 | 42 | 42 |

| WG60 | 6060 | 375,00 | 343,00 | 342,00 | 127.00 | 38.10 | 38.10 | 42 | 42 |

| WG70 | 7060 | 425,00 | 375,00 | 374,00 | 153.00 | 51.00 | 51.00 | 51 | 51 |

| WG80 | 8065 | 445,00 | 349.0 | 393,00 | 165,00 | 51.00 | 51.00 | 55 | 55 |

| WG100 | 10085 | 559,00 | 495,00 | 494,00 | 216.00 | 51.00 | 51.00 | 72 | 72 |

"G": nataasje stiet foar lasrelief

Las-op-hubs

WH Las-op-Hubs

| Hub-referinsje | Bushgrutte | A | B | C | D | E | F | Fl X | |

| WH12 | 1210 | 70 | 65 | 64.5 | 25 | 9 | 10 | - | - |

| WH16-1 | 1610 | 80 | 75 | 74.5 | 25 | 9 | 10 | - | - |

| WH20 | 2012 | 95 | 90 | 89.5 | 32 | 12 | 12 | - | - |

| WH25 | 2517 | 115 | 110 | 109.5 | 44 | 19 | 15 | - | - |

| WHG30-2 | 3020 | 145 | 140 | 139.5 | 50 | 20 | 15 | 17 | 17 |

| WHG35 | 3525 | 190 | 180 | 179.5 | 65 | 25 | 25 | 22 | 22 |

| WHG40-1 | 4030 | 200 | 190 | 189.0 | 76 | 32 | 30 | 25 | 25 |

| WHG40-2 | 4040 | 200 | 190 | 189.0 | 101 | 32 | 30 | 34 | 34 |

| WHG45-1 | 4535 | 210 | 200 | 199.5 | 89 | 40 | 30 | 30 | 30 |

| WHG45-2 | 4545 | 210 | 200 | 199.5 | 114 | 40 | 30 | 38 | 38 |

| WHG50-1 | 5040 | 230 | 220 | 219.5 | 102 | 40 | 35 | 34 | 34 |

| WHG50-2 | 5050 | 230 | 220 | 219.5 | 127 | 40 | 35 | 42 | 42 |

"GH": nataasje stiet foar lasferliening

WMG Las-op-Hub

| Hub-referinsje | Bushgrutte | A | B | C | D | E | F | Fl | X |

| WMG12 | 1210 | 70 | 60 | 58 | 26 | 9 | 10 | 9 | 9 |

| WMG16-1 | 1610 | 83 | 70 | 68 | 26 | 9 | 10 | 9 | 9 |

| WMG16-1 | 1615 | 83 | 70 | 68 | 38 | 16 | 11 | 13 | 13 |

| WMG20 | 2012 | 95 | 90 | 88 | 32 | 12 | 12 | 11 | 11 |

| WMG25 | 2517 | 127 | 110 | 108 | 44 | 19 | 13 | 15 | 15 |

| WMG30-2 | 3020 | 150 | 130 | 125 | 50 | 20 | 15 | 17 | 17 |

| WMG30-3 | 3030 | 150 | 130 | 125 | 76 | 25 | 19 | 25 | 25 |

| WMG35 | 3535 | 184 | 155 | 151 | 89 | 32 | 25 | 30 | 30 |

| WMG40 | 4040 | 225 | 195 | 187 | 102 | 32 | 32 | 34 | 34 |

| WMG45 | 4545 | 254 | 220 | 213 | 114 | 38 | 38 | 38 | 38 |

| WMG50 | 5050 | 276 | 242 | 228 | 127 | 38 | 38 | 42 | 42 |

Lasnaven binne makke fan C20 stiel en binne boarre, getapt en konysk foarme om tapse slotbussen te passen. Se kinne brûkt wurde foar it lassen yn katrollen, tandwielen, koppelingen, fanrotoren, riemtsjillen, ensfh. Dizze komponinten moatte feilich op 'e assen monteard wurde. Fjouwer soarten lasnaven binne standert beskikber. Type: W, WG, WH, WHG, WM, WMG tapse boringnaven.